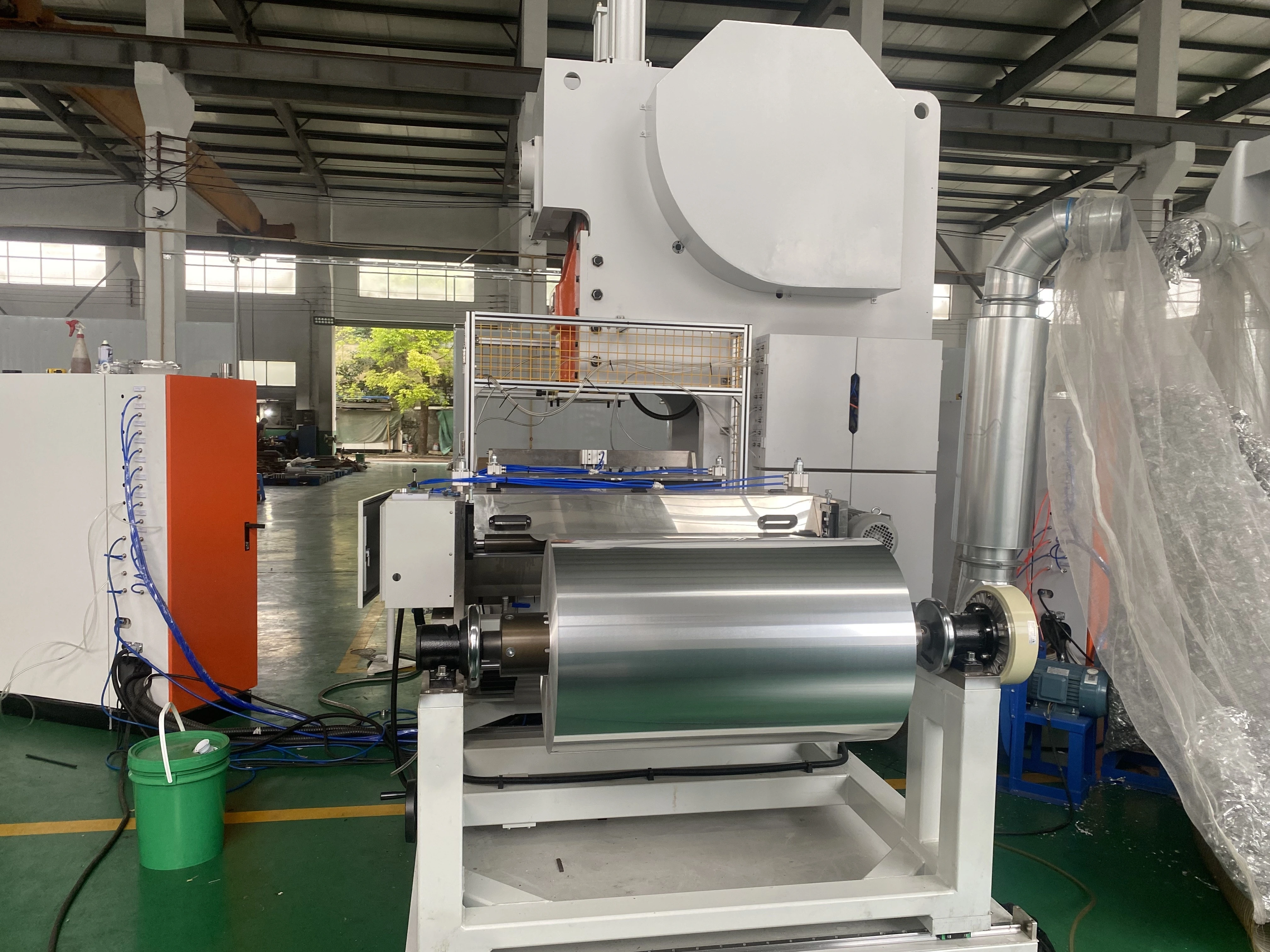

LK-T63 Innovative 3 Cavity 50 Strokes Per Minute Pan Aluminium Foil Food Trays Production Line

一、Product Detailed Description

1.Purpose-Built for Efficient Output

Do you need equipment that balances output with investment? The LK-T63 is developed specifically for 3-cavity molds and medium/small container production. Its C-frame is structurally reinforced to maintain stable rigidity under 63 tons of pressure, forming the foundation for smooth operation at 35 to 68 strokes per minute, which helps keep product defect rates low.

2.How "Single-Operator" Simplifies Management

Facing rising labor costs and a shortage of skilled workers, operational simplicity is key. The LK-T63 production process is fully automated—from feeding and stamping to stacking, requiring no manual intervention. The operator's main responsibilities are monitoring operation, replenishing raw material, and transferring finished goods. The intuitive touchscreen interface is designed for practicality, lowering the skill barrier.

3.Smart Features for Enhanced Flexibility

To adapt to changing market demands, the LK-T63 integrates several efficiency-boosting features:

-

Quick Mold Change System: The worktable is equipped with a lifting arm to simplify mold handling. A single operator can complete a changeover in a short time, accelerating order response.

-

Multi-Set Parameter Memory: The touchscreen can store up to 60 sets of mold production parameters. One-touch recall during product switches eliminates repetitive setup, reducing material and time waste.

-

Operation Status Monitoring: The system performs real-time fault diagnosis. Error messages are clearly displayed on the screen, and the machine stops automatically, aiding quick troubleshooting and preventing larger losses.

4.Configuration Choices for Long-Term Operation

The long-term value of equipment lies in stability and durability. We have selected industrially proven components for critical areas:

-

Drive Unit: Powered by a Siemens industrial motor with matched ABB control, providing smooth power for continuous operation.

-

Control System: Main control components (PLC, HMI, etc.) use Mitsubishi products to ensure reliable control.

-

Frame & Actuation Components: Constructed with practical materials. Pneumatic components from SMC/AirTAC ensure consistent action and durability.

5.Complete Production Solution

We provide a ready-to-run, complete production line. The standard configuration includes: Servo feeder, 63-ton punch press, mold lifter arm, safety doors, scrap collection device, control cabinet, and 3-cavity stacker. Detailed installation guides are provided, and on-site technical support is available to help you start production quickly.

二、Aluminum foi container making machine product specifications

| Item | Description |

|---|---|

| Model | LK-T63 |

| Nominal Pressure | 63 Tons |

| Standard Mold Cavities | 3 Cavities |

| Production Speed | 35 - 68 Strokes/Minute |

| Average Operating Speed | ~50 Strokes/Minute |

| Theoretical Hourly Output | ~9,000 - 12,000 pcs (3-cavity) |

| Total Power | ~19.8 KW |

| Power Supply | 380V / 50Hz / 3-Phase (Adaptable) |

| Machine Weight | ~13,500 KG |

| Main Drive Motor | Siemens |

| Control System | Mitsubishi PLC & Touchscreen HMI |

三、Key Benefits for Your Operation

-

Simplified Labor Setup: Fully automated process design enables single-operator monitoring, reducing reliance on manpower and long-term labor costs.

-

Stable, Substantial Output: Purpose-driven design combined with an average speed of 50 strokes/minute ensures consistent production with stable合格率.

-

Agile Order Response: Quick mold change and parameter memory functions improve production changeover efficiency for handling multi-variety orders.

-

Clear Maintenance Diagnostics: Visual fault information and easy replacement of wear parts lower maintenance difficulty and the risk of unplanned downtime.

-

Good Equipment Reliability: Key components from established industrial brands enhance overall operational stability and expected service life.

-

Adequate Safety Protection: Standard safety doors with interlocked stop function provide necessary protection for operators.

-

Reliable Experience Support: Based on over 15 years of design, manufacturing, and export experience, with performance validated across multiple markets.

四、Aluminum foil container making machine sample

五、Customer Questions about aluminum foil container making machine

Q: With an average speed of 50 strokes/min, what is the approximate daily output?

A: Calculating based on 20 hours of effective production per day using a 3-cavity mold, the theoretical daily output is between 180,000 and 240,000 pieces. Actual output will vary slightly depending on product size and production rhythm, but it is sufficient to meet the main capacity needs of a medium-sized factory.

Q: What specific tasks does the "single operator" handle?

A: The operator's role is greatly simplified. Main responsibilities include: checking if the equipment is running normally, changing aluminum coils on the feeder, transferring stacked finished products, and performing scheduled mold changes. The feeding, forming, counting, and stacking processes during production are all automated.

Q: How does the parameter memory function help factories with many product types?

A: This function directly addresses the time-consuming setup issue in multi-variety production. You can save a set of parameters for each mold. When producing that item again, recalling the corresponding number allows the machine to prepare quickly, reducing changeover preparation time and setup material waste.

Q: When a fault occurs, how can we initially identify the problem?

A: The equipment has self-diagnostic capabilities. When an issue arises, clear prompt messages such as "Feeding Error" or "Lubrication Alert" will be displayed on the touchscreen. You can perform basic checks based on these prompts. If further assistance is needed, informing our technical support of the prompt code helps locate the problem faster.

Q: Can it produce both wrinkled and wrinkle-free containers?

A: Yes. The LK-T63 accommodates both mainstream processes. The main difference lies in mold design. After you provide samples or drawings, we will design and supply the corresponding molds to ensure production results.

Q: Which parts are regular consumables? What is the daily maintenance?

A: Regular attention focuses on a few sensors and controllers in the feeding mechanism; these are standard parts and easy to replace. Daily maintenance mainly involves periodic lubrication as per the manual. The tools and manual provided with the machine can guide most routine tasks.

Q: How long does installation and commissioning take? Can we do it ourselves?

A: For teams with basic electromechanical knowledge, following our provided videos and manual, mechanical installation and basic commissioning can be completed within a few days. Typically, about one week is needed from equipment placement to producing qualified samples. We also offer optional engineer on-site service.

WhatsApp: 0086-18930097829