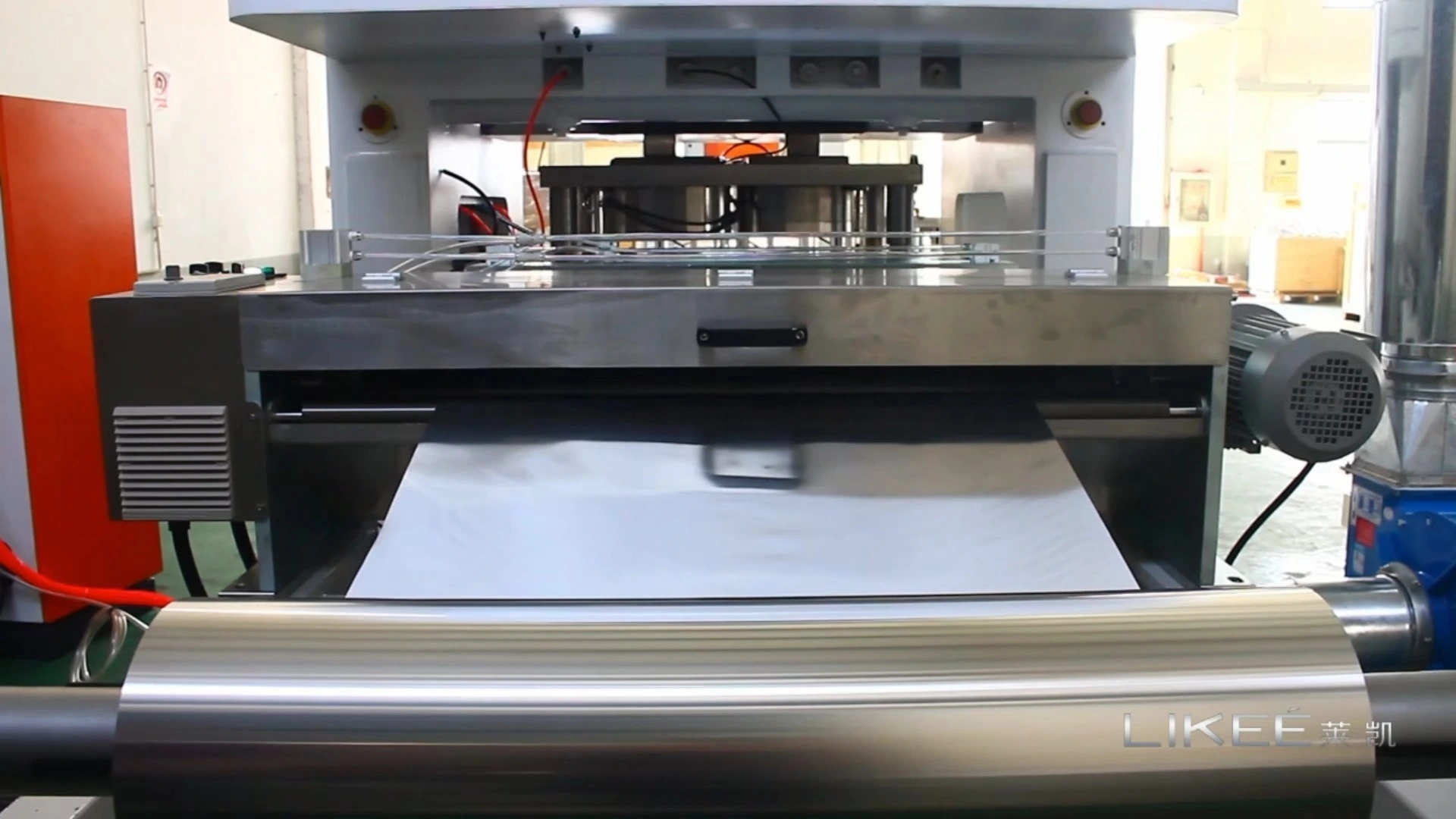

LK-T80 Food Container Recyclable Aluminum Foil Container Pan Tray Forming Machine

一、Aluminum foil container making machine introduction

The LK-T80 Aluminum foil container making machine is a high-efficiency, fully automatic aluminum foil container production line integrated with scrap aspirator and baler, truly achieving closed-loop "production-collection-processing" management. With 80-ton pressure and H-frame structure, it features standard 4-cavity molds and consistently produces 9,000-12,000 containers per hour. The entire process requires only one operator with high automation levels.

The scrap aspirator automatically collects trim waste generated during stamping, maintaining a clean production area. The scrap baler compresses collected scrap into compact blocks, significantly reducing storage space and facilitating recycling. This not only improves workshop management efficiency but directly lowers waste processing costs.

二、Aluminum foil container making machine key Features

1.Complete Closed-loop Production System

-

Scrap suction machine automatically collects trim waste, eliminating manual cleaning

-

Baler compresses scrap, reducing volume by over 60%

-

Overall design complies with environmental production standards

2.Efficient & Stable Operation

-

H-frame structure ensures stable 24-hour continuous operation

-

Sealed lubrication system reduces oil contamination, extending equipment life

-

Intelligent control interface, simple and intuitive operation

3.Integrated Intelligent Control

-

Touchscreen controls production, suction, and baling processes

-

Automatic fault alarms for quick problem identification

-

Real-time production data recording for management analysis

三、Aluminum foil container making machine technical specifications

| Item | Specification | Notes |

|---|---|---|

| Main Machine | LK-T80 | 80-ton pressure, H-frame |

| Standard Molds | 4 cavities | Expandable to 6 cavities |

| Production Speed | 35-68 strokes/min | Average 50 strokes/min |

| Waste Processing | Suction machine + Baler | Integrated control system |

| Waste Compression | ≥60% | Significantly saves storage space |

| Operators Required | 1 person | Full-process automation |

四、Aluminum foil container making machine detail

五、Global Customers

六、Exhibition

七、Customer Concerns

Q1: Are scrap suction machine and baler standard equipment?

Yes, both are part of the LK-T80 Aluminum foil container making machine standard configuration. The suction machine automatically collects all trim waste during production, while the baler compresses it into neat blocks—the entire process requires no manual intervention.

Q2: How much space does the waste processing system save?

After baling, scrap volume reduces by over 60%. Loose scrap originally requiring 10 cubic meters needs less than 4 cubic meters after compression, significantly saving workshop storage space.

Q3: How much additional power does waste processing consume?

The baler uses 5.5KW power with intermittent operation mode—it automatically starts only when scrap accumulates to a certain level. Actual power consumption is minimal, not affecting overall energy efficiency.

Q4: How is this system maintained?

Mainly clean the suction machine filter screen and regularly check the baler hydraulic system. Maintenance is simple—monthly checks suffice. We provide detailed operation manuals.

Q5: Can waste processing be added later if only buying the main machine?

Yes, but purchasing and installing separately costs more and requires production line modifications. We recommend choosing the complete configuration initially for better integration and cost advantages.

WhatsApp: 0086-18930097829