How to Optimize Your Aluminum Foil Packaging Process with Modern Machines

Aluminum foil is a versatile material known for its exceptional properties. One of its most significant benefits is its unparalleled ability to preserve freshness and protect products from contamination. Whether youre packaging foods, electronics, or travel goods, aluminum foil ensures that your items remain in pristine condition throughout the supply chain.

In the food industry, aluminum foil is a go-to material for wrapping and storing perishables. It effectively blocks moisture, air, and light, which are major causes of spoilage. For example, in a study conducted by the National Food Authority, aluminum foil was found to reduce the rate of oxidation and enzymatic browning in fruits and vegetables by up to 50%. This not only extends the shelf life of these products but also reduces waste and associated costs.

Beyond food packaging, aluminum foil is also widely used in electronics and automotive industries. For instance, its commonly used to protect small electronic components during shipping and storage. In the automotive industry, aluminum foil can be used to create dashboard protectors that shield delicate surfaces from scratches and damage.

The Importance of Aluminum Foil in Packaging

Aluminum foil packaging offers a multitude of advantages across various industries. Its protective qualities make it indispensable for preserving the integrity of packaged goods. Lets delve into some specific applications where aluminum foil plays a crucial role:

1. Food Packaging: Aluminum foil is often used to package fresh produce, cooked meals, and baked goods. It ensures that the items stay fresh longer, maintaining their texture and flavor.

Travel Goods: In the travel industry, aluminum foil is used to store toiletries and medications. Its moisture-resistant properties make it ideal for keeping products safe and dry during transport.

Electronics Industry: In this sector, aluminum foil is used to shield delicate electronic components from damage during storage and transportation. It helps prevent corrosion and ensures that the components remain functional.

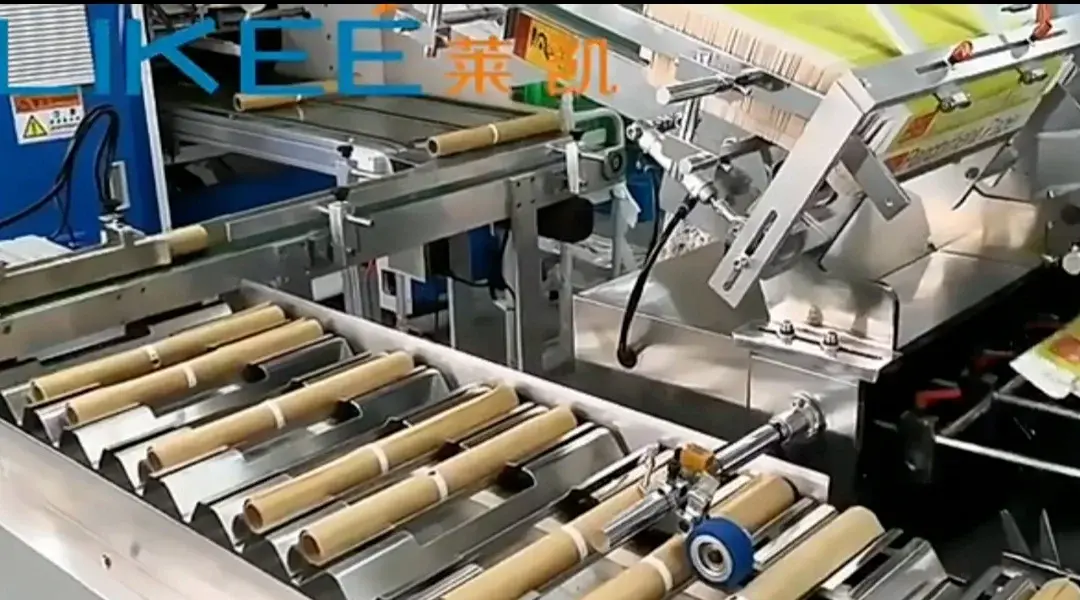

Key Features of Advanced Aluminum Foil Packaging Machines

Modern aluminum foil packaging machines are engineered to enhance efficiency and reduce waste. These machines are equipped with advanced features that streamline the entire process, from cutting and sealing to unrolling and packaging.

1. Precision Cutting: Modern machines use sophisticated cutting mechanisms that ensure uniform and precise cuts. This reduces waste and ensures that each package is exactly the right size and shape.

- Sealing: Sealing is a critical step in the packaging process. Advanced machines use heat-sealing technology to create a strong, airtight seal that prevents leakage and contamination. Sensors and feedback systems ensure that the seal is perfect every time.

- Automated Folding: Automation plays a vital role in reducing human error and improving efficiency. Modern machines can fold and shape aluminum foil with precision, eliminating the need for manual labor and improving consistency.

- Speed and Consistency: One of the most significant advantages of modern machines is their ability to produce packages at high speeds while maintaining consistency. This not only speeds up the production process but also reduces the risk of errors and downtime.

Implementing Aluminum Foil Packaging Machines in Your Workflow

Integrating modern aluminum foil packaging machines into your existing processes involves several steps. Heres how you can smoothly transition to these machines:

1. Assess Your Needs: Begin by analyzing your current packaging operations. Identify areas where you can improve and determine whether an aluminum foil machine is the right solution. Consider factors like production volume, product type, and specific packaging requirements.

2. Start Small: If youre new to modern packaging machines, start with a smaller machine that can handle basic tasks. This will give you a chance to understand the machines capabilities and make necessary adjustments before a full investment.

3. Invest in Training: Ensure that your team is well-trained on operating the new machines. Provide comprehensive training sessions to help employees become proficient and comfortable with the technology.

4. Monitor Performance: Once the machine is in operation, monitor its performance closely. Pay attention to any inconsistencies or issues and address them promptly. Regular maintenance and inspections are crucial to prevent costly downtime.

5. Scale Up Gradually: As you become more comfortable with the machine, consider scaling up your operations. This will help you maximize the benefits of the new technology without overwhelming your existing resources.

Case Study: A Manufacturers Journey to Modern Packaging

To understand the real-world impact of modern aluminum foil packaging machines, lets look at a case study involving a European manufacturer. This company was previously using traditional packaging methods, which were slow and inefficient. They experienced high levels of waste and were producing defective packages frequently.

After conducting a thorough assessment, the company decided to invest in a modern aluminum foil packaging machine. The transition was seamless, and the results were dramatic. The new machine was able to produce foil at a rate 40% faster than their old machines, significantly reducing production time.

Moreover, the machine greatly reduced waste, with a 25% reduction in defective packages. This resulted in substantial cost savings and improved overall efficiency. Employee morale also improved, as the new machine was easier to use and operate.

Embracing Modern Technology for Competitive Advantage

In a rapidly evolving market, staying ahead of the curve is essential. Opting for modern aluminum foil packaging machines is a smart move that can significantly enhance efficiency, reduce costs, and improve sustainability. By investing in these technologies, you can optimize your processes, reduce waste, and achieve your business goals.

So, take the first step today. Explore the benefits of modern aluminum foil packaging machines and implement the right technology for your needs. By embracing modern technology, you can position your business for long-term success in the competitive packaging industry.

By optimizing your aluminum foil packaging process with modern machines, youre not just improving efficiencyyoure investing in a future thats sustainable, efficient, and profitable.

WhatsApp: 0086-18930097829