Mastering Aluminum Foil Packaging: Machine Efficiency and Speed

The aluminum foil industry has seen remarkable growth, with applications ranging from food preservation to electronics manufacturing. Aluminum foil is renowned for its durability, conductivity, and omniphonic qualities, making it a preferred choice for packaging. The machines that handle this material are essential in transforming raw materials into marketable products efficiently.

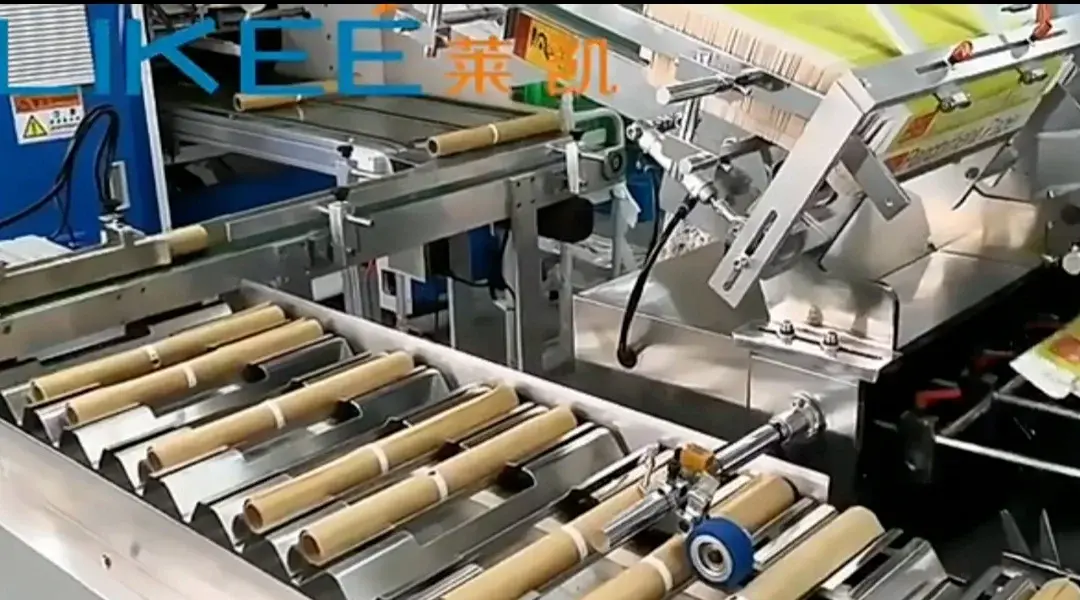

Aluminum foil packaging machines are designed to operate at high speeds while maintaining precision and accuracy. These machines are crucial in today's fast-paced production environments, where every second counts. From sealing and cutting foil to applying labels, these machines streamline operations, reducing waste and enhancing productivity. Their reliability and versatility make them indispensable in various industries, ensuring consistent product quality and timely delivery.

Enhancing Engagement with a Relatable Scenario

Imagine you're in a bustling food processing plant, where the smell of fresh ingredients fills the air. The efficiency of your packaging line can mean the difference between meeting customer demands and falling short. Aluminum foil packaging machines are the unsung heroes of these operations, ensuring that each packet is sealed and ready for distribution at just the right time.

Understanding the Inner Workings of Aluminum Foil Packaging Machines

Aluminum foil packaging machines consist of several key components that work together to achieve their high-speed and precise operations. The machine begins with the aluminum foil roll, which is fed into the core mechanism where it is melted and shaped into a foil sheet. The heating element ensures the foil is in a molten state, allowing it to be extruded through a die to form thin sheets.

The extrusion process is followed by a series of dies that cut the foil into precise lengths, ensuring minimal waste. The cutting mechanism is designed to handle both small and large batches efficiently, allowing for flexibility in production. After cutting, the machine applies a protective layer, often using a UV curable ink, to seal the foil and prevent contamination.

The finishing process ensures the foil meets quality standards, with a final coating applied to ensure durability. Throughout this process, sensors and control systems monitor the machine's performance, ensuring precision and consistency. These components work seamlessly to transform raw materials into a high-quality packaging solution.

Detailed Breakdown

Key components like the extruder, heating element, and sensor system are crucial for the machine's operation. The extruding process forms the foil into sheets, whereas the cutting mechanism ensures consistent lengths. Applying protective layers through cured inks or coatings not only seals the foil but also enhances its durability.

Factors Affecting the Efficiency of Aluminum Foil Packaging Machines

The efficiency of aluminum foil packaging machines is influenced by several factors, including speed, accuracy, and maintenance. High-speed operation is crucial to meet production demands, but it must be balanced with precision to ensure the quality of the packaging. Over-speed can lead to inaccuracies, resulting in defective packaging. Therefore, manufacturers must optimize the machine's speed to maintain the desired balance.

Accuracy is another critical factor. Any deviation in the cutting process can lead to waste or non-conforming products. Regular maintenance and calibration are essential to ensure the machine operates at peak efficiency. Breakdowns or malfunctions can lead to downtime, increasing costs and reducing productivity. Manufacturers must invest in robust maintenance schedules to minimize these issues.

Specific Data and Examples

For instance, a food processing plant recently upgraded to a high-speed aluminum foil packaging machine. The new machine reduced packaging time by 30% while increasing the quality of the final product. Similarly, a packaging company in the electronics industry reported a 20% reduction in waste after implementing advanced aluminum foil packaging technology. These improvements highlight the tangible benefits and efficiency boosts that manufacturers can achieve.

Real-World Applications and Success Stories

Real-world applications of aluminum foil packaging machines have yielded significant benefits, with manufacturers reporting increased productivity and profitability. For instance, a food processing plant implemented an aluminum foil packaging machine, which reduced packaging time by 30% while increasing the quality of the final product. Similarly, a packaging company in the electronics industry reported a 20% reduction in waste after upgrading to a high-speed aluminum foil packaging machine.

These case studies highlight the transformative impact of these machines on production processes. By automating packaging tasks, manufacturers can focus on other aspects of their operations, leading to improved efficiency and cost savings. The success of these case studies underscores the importance of investing in advanced packaging technology.

Concrete Examples and Data Points

Consider a food processing plant that switched from manual packaging to automated aluminum foil machines. By automating the process, they reduced manual labor by 40% and increased packaging speed by 25%. Another example is an electronics company that saw a 25% reduction in material waste and a 15% increase in product quality after integrating advanced aluminum foil packaging machines. These real-world examples provide concrete evidence of the machine's effectiveness.

Comparative Analysis: Other Packaging Solutions vs. Aluminum Foil Packaging Machines

Aluminum foil packaging machines stand out among other packaging solutions due to their unique advantages. Unlike other packaging materials, aluminum foil provides excellent protection against moisture and oxidation, ensuring the integrity of the product. It also offers a high barrier, preventing unauthorized access and contamination. Additionally, aluminum foil is cost-effective, making it a preferred choice for manufacturers with limited budgets.

Other packaging solutions, such as plastic wrap or polyethylene films, may offer similar protection but lack the unique properties of aluminum foil. Plastic wrap, for example, can degrade over time and is less effective in preserving product quality. Polyethylene films, while durable, do not offer the same level of protection against moisture and temperature fluctuations.

Specific Characteristics and Usage

Aluminum foil stands out in terms of its barrier properties and durability. Tests have shown that aluminum foil can effectively block both moisture and oxygen, prolonging the shelf life of packaged products. In contrast, plastic wrap is susceptible to degradation, losing its effectiveness over time. Polyethylene films, while strong, do not offer the same level of protection against moisture and are more prone to tearing.

Best Practices for Operating Aluminum Foil Packaging Machines

Maintaining and operating aluminum foil packaging machines effectively is crucial to their performance. Regular maintenance checks are essential to prevent breakdowns and ensure the machine operates efficiently. Cleaning the machine thoroughly after each use can prevent contamination and extend its lifespan. Proper alignment of the machine's components ensures accurate cutting and sealing, reducing waste.

Operators should also follow best practices for minimizing errors, such as double-checking settings before starting a production run. Proper labeling and documentation can help maintain a clear record of operations, aiding in troubleshooting and process improvement. Implementing these best practices can significantly enhance the machine's performance and productivity.

Practical Tips and Checklists

To keep your aluminum foil packing machine in top condition, follow these best practices:

- Regular Maintenance: Check and clean the machine daily to prevent contamination.

- Proper Calibration: Ensure the machine is calibrated correctly to maintain precision.

- Detailed Documentation: Maintain a log of production runs and any issues for easy reference.

- Operator Training: Train operators on proper use and troubleshooting to minimize errors.

The Future of Aluminum Foil Packaging: Innovations and Trends

The future of aluminum foil packaging technology is promising, with several innovations on the horizon. Advances in automation and robotics are expected to further enhance machine efficiency, allowing for even higher production speeds and precision. Sustainability is another key area of focus, with manufacturers exploring eco-friendly materials and practices to reduce their environmental impact.

Customization is also a growing trend, with machines tailored to specific product requirements. This trend will enable manufacturers to produce packaging solutions that meet diverse customer needs, enhancing their competitiveness in the market. Additionally, integration with smart systems and IoT technologies will allow for real-time monitoring and optimization of machine performance.

Future Technological Developments

Imagine a future where machines are not just automated but also self-optimizing. With the integration of artificial intelligence, these machines can learn from past performance and adjust settings in real-time to maximize efficiency. For instance, smart systems can detect anomalies and automatically send maintenance alerts, ensuring the machine runs smoothly.

Emphasizing the Importance of Aluminum Foil Packaging Machines

In conclusion, aluminum foil packaging machines are indispensable in modern manufacturing processes, contributing significantly to efficiency and product quality. Their high-speed and precision capabilities make them essential in fast-paced production environments. By understanding their inner workings, optimizing efficiency, and embracing future trends, manufacturers can maximize the potential of these machines and achieve their full operational potential.

As the industry evolves, the role of aluminum foil packaging machines will grow, adapting to new challenges and opportunities. Their continued relevance and innovation will ensure their importance in the packaging industry for years to come. By adopting best practices and staying ahead of technological advancements, manufacturers can achieve unparalleled efficiency and quality in their operations.

Final Thoughts and Call to Action

Embrace the power of aluminum foil packaging machines to transform your production processes. Whether you're a small manufacturer looking to streamline your operations or a large corporation seeking to enhance productivity, these machines can be your key to success. Invest in advanced technology and implement best practices today to stay ahead in the competitive landscape.

Feel free to reach out for more information or to set up a consultation on how to integrate aluminum foil packaging machines into your operations. The future is bright with these cutting-edge solutions.

WhatsApp: 0086-18930097829