Mitsubishi Aluminum Foil Kitchen Roll Slitter Rewinding Machine Semi Automatic Fast Speed

Mitsubishi Aluminum Foil Kitchen Roll Slitter Rewinding Machine Semi Automatic Fast Speed

Product Description

LK-SR450 is use for rewinding the jumbo roll of aluminium foil / baking paper / cling bag into small roll. It adopts surface and center rewinding method, it can rewind the roll from 1 meter for house foil roll, kitchen foil roll, and catering foil roll etc. It could feeding paper cores, rewinding by meters, sealing(sealing by hot melt glue system) the finishes rolls and transferring automatically with 6 shafts revolver type system automatic changes without stop.High speed household aluminum foil rewinding machine LK-SR450 is suitable for the production of high-meter aluminum foil rolls, baking rolls for food service use.The advantages: -Using Omron encoder to fix length with high accuracy-Automatic cut-station indexing- With electronic brake-Stepper division angle-Automatic tension control.

Technical Parameters:

| Technical Parameter | Description |

|---|---|

| Product Name | Semi Automatic aluminum foil rolling and rewinding machine |

| Electric | 380V, 50HZ, 3Phase |

| Rewinding Speed | 0-350m/min |

| Rewinding Roll Width | 100-50mm |

| Cardborad core thickness | Not Less Than 3mm |

| Inner core diameter of the mother roll | 76mm Or 152mm |

| Gluing way | Manual |

| Rewinding Roll Outer Diameter | 45-130mm |

| Mother roll diameter | 700mm |

| Air supply | 0.6-0.8Mpa |

| Number of spindles | 2 |

| Product Name | Semi Automatic Foil Cutter Rewinding Machine |

| Product Name | Aluminum Foil Roll Food Packaging Rewinding Machine |

Applications:

The machine is designed to rewind rolls with an outer diameter of 45-130mm and a cardboard core thickness of not less than 3mm. It is suitable for mother rolls with a diameter of up to 700mm and an inner core diameter of 76mm or 152mm. The LIKEE Lk-SR450 is perfect for use in different scenarios and occasions, including:

- Household Use: The LIKEE LK-SR450 is perfect for use in households to rewind aluminum foil rolls. The machine makes it easy to cut and rewind aluminum foil, making it easy to use in different settings.

- Restaurant and Catering: The LIKEE LK-SR450 is perfect for use in restaurants and catering businesses. The machine can handle large rolls of aluminum foil, making it easy to cut and rewind aluminum foil for different purposes.

- Food Packaging: The LIKEE LK-SR450 is perfect for use in food packaging businesses. The machine can handle different sizes of aluminum foil rolls, making it easy to cut and rewind aluminum foil for different food packaging purposes.

- Retail Stores: The LIKEE LK-SR450 is perfect for use in retail stores that sell aluminum foil. The machine makes it easy to cut and rewind aluminum foil rolls, making it easy for customers to buy aluminum foil in different sizes.

The LIKEE Lk-SR450 is a semi-automatic aluminum foil rolling and rewinding machine that is perfect for use in different scenarios and occasions. The machine is easy to use and can handle different sizes of aluminum foil rolls, making it a versatile machine for different businesses.

Packing and Delivery:

1. Before packing we must test the machine and mold to run properly.

2. Stable package professional and skilled loader reduce damage of product during transport.

3. We fixed our machine in container which will be protected well during shipping.

4. We use the wooden cabinet, protect the machine and mold during shipping.

Company Brife Introduction:

LIKEE has adhering to the principle “Always endeavoring to do still better”. Holding the concept of scientific and technological innovation and environmental protection, the concept of "Environmental Protection, Innovation and Win-win" runs through the product life cycle of R & D, production, logistics and customer service, complying with the mainstream and trend of the development of aluminum foil industry to realize the society and environment.

LIKEE is specialized in R & D and manufacturing aluminum foil container making machine and molds since 2010. With the increasing innovation ability, outstanding flexible customization ability, LIKEE provides many effective automatic production scheme to numerous new and old customers all over world. Greatly and effectively reduce the production waste rate, reduce the production cost and improve the production efficiency.

FAQ

Q1: Do you accept customized orders?

A: Yes, we do.

Q2: what about leadtime?

A: The fastest delivery can be 5~6 weeks once the order is confirmed.

Q3: What are the terms of payment and currencies do you accept?

A: T/T, L/C at sight ,Cash,Paypal,Western Union.

Q4: How to purchase raw material or lubricating oil?

A: LIKEE can support every purchase work for all our customers, to help you set up a matured factory at the fast step.

Q5: Warranty for machines and moulds?

A: We gurantee a period of 12 months from the date of machine & mould installation and setting to work.

Q6: How to install machine and train our staff on our factory?

A: Yes, we do. We’ll send our engineers to your factory to install, test machines and give your workers training guidance.

Q7: How to contact ?

A: Whatsapp No. 008618930097829

Email: tina@likee.com.cn

Reliable Aluminum Foil Rewinding

High quality LK-SR450 semi-automatic aluminum foil rewinding machine, made in China, offers high speed and precision rewinding, with automatic cut-station indexing and electronic brake. It rewinds jumbo rolls of aluminum foil, baking paper, and cling bags into small rolls, and comes with a 12-month warranty. Additionally, LIKEE provides installation, training, and ongoing service support for all customers, ensuring a smooth and efficient production process.

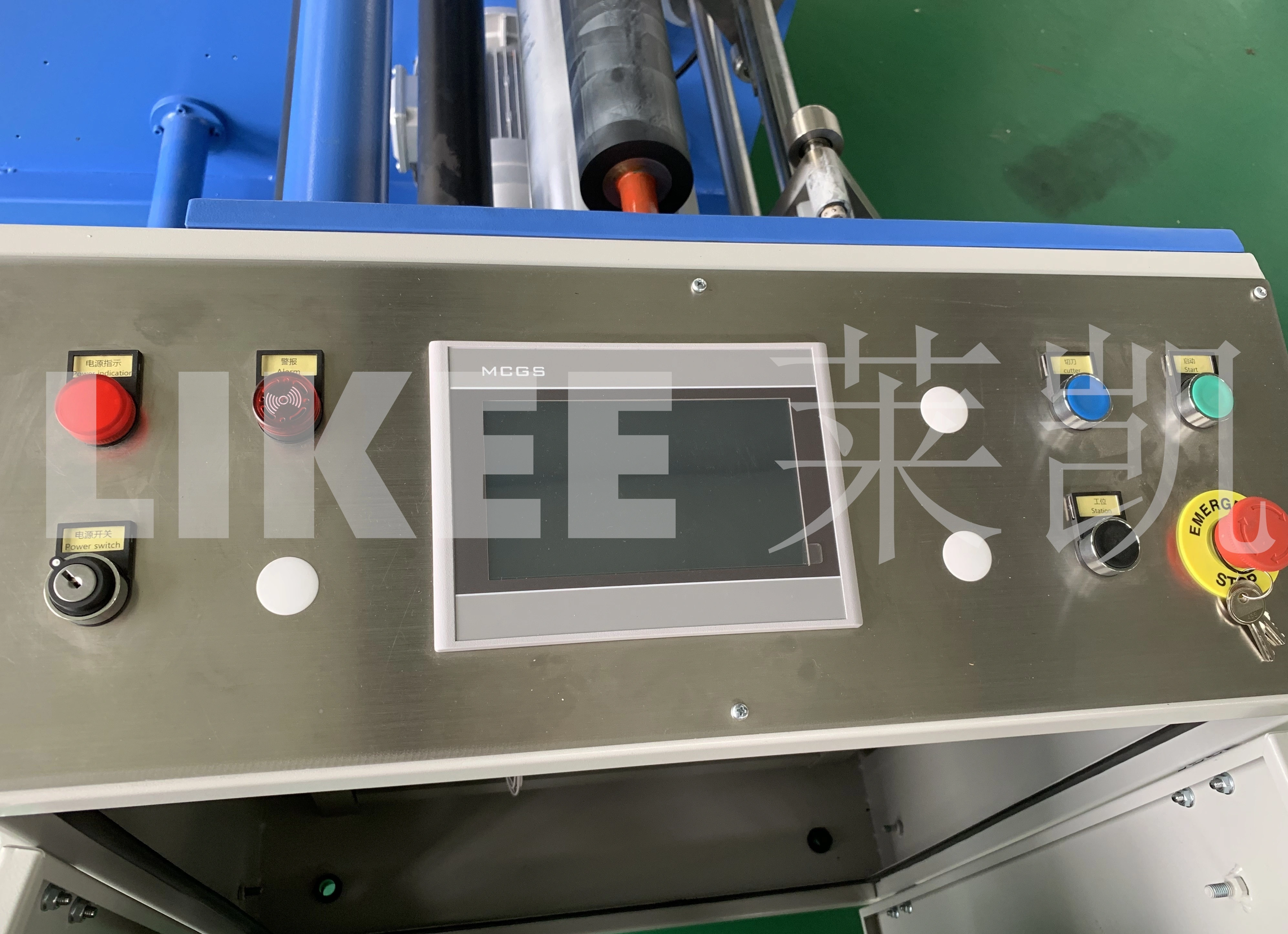

Product Display

Reliable

Reliable Semi-Auto Aluminum Foil Rewinder

The LK-SR450 semi-automatic aluminum foil rewinding machine offers high-speed performance for the production of high-meter aluminum foil rolls and baking rolls for food service use. It features an Omron encoder for high accuracy, automatic cut-station indexing, electronic brake, and stepper division angle, as well as automatic tension control. With a solid structure and advanced features, this machine is suitable for rewinding jumbo rolls of aluminum foil, baking paper, and cling wrap into small rolls, providing an efficient and reliable solution for packaging needs. Additionally, the product comes with after-sales service and customer support, providing a comprehensive solution for businesses in the packaging industry.

Application Scenario

Material Introduction

The high-quality LK-SR450 semi-automatic aluminum foil rewinding machine is made in China with after-sales service. It is suitable for the production of high-meter aluminum foil rolls, baking rolls for food service use. The machine uses Omron encoder to fix length with high accuracy and automatic cut-station indexing equipped with an electronic brake and automatic tension control for optimal performance. It is capable of rewinding the jumbo roll of aluminum foil, baking paper, and cling bag into small rolls, providing an efficient and effective solution.

FAQ

WhatsApp: 0086-18930097829