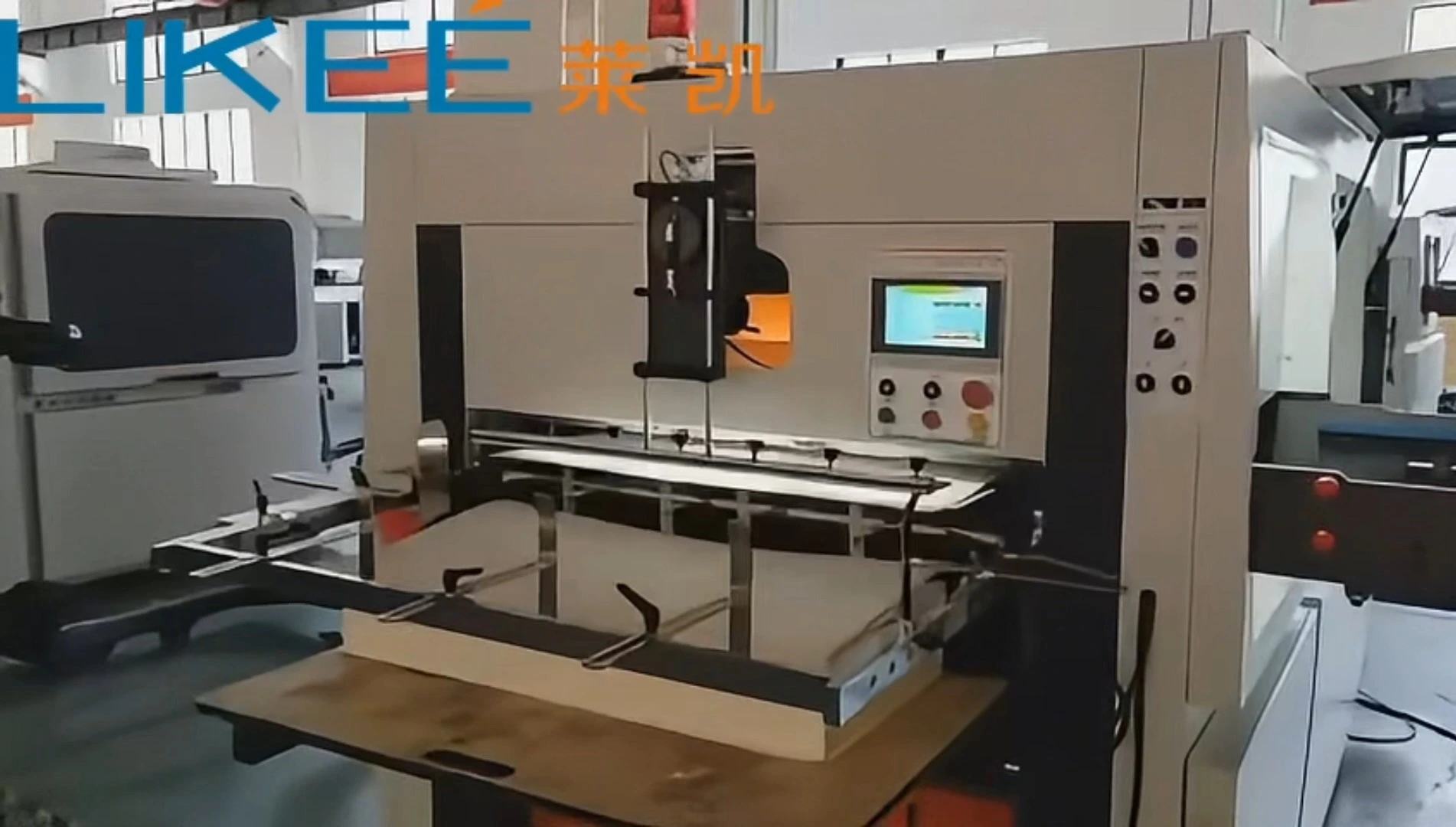

LKD 970 Automatic Aluminum Foil Die Cutting Machine High Precision Paper Cutting Machine 100-180 times/min

LKD 970 Automatic Aluminum Foil Die Cutting Machine High Precision Paper Cutting Machine 100-180 times/min

1. Advantage: high stability, high performance, high precision of the finished product;

2. Usage: widely used in printing, packaging and paper products industries;

3. Configuration: all the key parts and controls of the machine are imported;

4. Lubrication System: Adopts forced lubrication system to ensure main driving oil supply regularly and reduce friction and prolong the machine life, machine will shut down for protection if oil pressure is low. The oil circuit adds a filter to clear the oil and a flow switch to monitor lacking oil.

5. The die-cutting force is provided by a 7.5KW inverter motor driver. It is not only power-saving, but also can realize the stepless speed adjustment, especially when coordinate with the extra large flywheel, which make the die-cutting force strong and steady, and the electricity can be further reduced.

6. Pneumatic clutch brake: through adjust the air pressure to control the driving torque, low noise and high brake performance. The machine will shut down automatically if overload happened, response sensitive and fast.

7. It can die-cut according to the printed words and figures or simply die-cut without them. The coordination between stepping motor and photoelectric eye which can identify colors assures the perfectly fit of the die-cutting position and figures. Simply set the feed length through the micro-computer controller to die-cut the products without words and figures.

Technical Parameters:

| Production Capacity | 100-180times/min |

| Total Paper | 12KW |

| Dimension | 5500*2200*1800mm |

| Cutting Pressure | 0.20mm |

| Airpressure Consumption | 0.5Mpa |

| Lcd | Touch Screen |

| Applicable Industries | Manufacturing Plant |

| Max Cutting Area | 940*610mm |

| Paper Gram Weight | 130-400g/squaremeter |

| Mac Cutting Pressure | 280T |

Company Brief Introduction

We LIKEE as a NATIONAL HIGH -TECH ENTERPRISE with abundant experience on the aluminum foil products automatic production solution since 2010.

With the rapid rise in the prices of paper and plastic, and more and more countries execute plastic abandonment, aluminum foil package material is the market tend over the word. The demand of aluminum foil containers, household aluminum foil roller, aluminum foil sheet and the other aluminum foil related products are increasing quickly over world.

LIKEE is specialized in R & D and manufacturing aluminum foil container making machine and molds since 2010. With the increasing innovation ability, outstanding flexible customization ability, LIKEE provides many effective automatic production scheme to numerous new and old customers all over world. Greatly and effectively reduce the production waste rate, reduce the production cost and improve the production efficiency.

LIKEE has adhering to the principle “Always endeavoring to do still better”. Holding the concept of scientific and technological innovation and environmental protection, the concept of "Environmental Protection, Innovation and Win-win" runs through the product life cycle of R & D, production, logistics and customer service, complying with the mainstream and trend of the development of aluminum foil industry to realize the society and environment.

FAQ

Q1: Do you accept customized orders?

A: Yes, we do.

Q2: what about leadtime?

A: The fastest delivery can be 5~6 weeks once the order is confirmed.

Q3: What are the terms of payment and currencies do you accept?

A: T/T, L/C at sight ,Cash,Paypal,Western Union.

Q4: How to purchase raw material or lubricating oil?

A: LIKEE can support every purchase work for all our customers, to help you set up a matured factory at the fast step.

Q5: Warranty for machines and moulds?

A: We gurantee a period of 12 months from the date of machine & mould installation and setting to work.

Q6: How to install machine and train our staff on our factory?

A: Yes, we do. We’ll send our engineers to your factory to install, test machines and give your workers training guidance.

Q7: How to contact ?

A: Whatsapp No. 008618930097829

Email: tina@likee.com.cn

Efficient Aluminum Foil Cover Production

Our LKD 970 die cutting machine is the perfect choice for the printing, packaging, and paper products industries, offering smooth and precise operations with advanced features like servo positioning and automatic counting, ensuring high-quality and efficient production. With a maximum cutting area of 940mmx610mm and the ability to handle paper gram weights from 134-400g/㎡, our machine is versatile and reliable, making it a valuable investment for your aluminum foil production line. Backed by our National High-Tech Enterprise certification and over a decade of experience, you can trust our LIKEE team to provide top-quality automatic machine & mold solutions, setting your factory up for success and sustainability in the packaging industry.

Product Display

Efficient, precise, versatile, automated

Efficient Aluminum Foil Die Cutting

The Automatic LKD 970 aluminum foil cover lid liner die cutting machine is a high-tech solution for aluminum foil production, offering precision cutting and smooth operations. With a cutting area of 940mmx610mm and a production capacity of 100-180 times/min, this machine is ideal for the printing, packaging, and paper products industries. Its micro-computer, human-computer control interface, and servo positioning ensure safety, reliability, and smooth movement, making it a valuable addition to any production line. The machine is equipped with a photoelectric deviation correction system, electromagnetic clutch centralized oil lubrication, and overload protection, guaranteeing steady pressure, precise positioning, and smooth movement. The high-quality key parts and controls imported from leading manufacturers further ensure the integrity and longevity of the machine. With a total power of 12KW and dimensions of 5500x2000x1800mm, this machine is a valuable investment for businesses looking to optimize their aluminum foil production. In addition to its technical specifications, the LKD 970 die cutting machine is backed by a professional team with expertise in R&D, production, and sales departments, delivering comprehensive support and service to customers. Furthermore, the machine is CE, SGS, ISO9001, and ISO14001 certified, further assuring its high-quality performance and environmental significance, making it an excellent choice for businesses focused on sustainable development and the production of top-quality aluminum foil products.

Application Scenario

Material Introduction

The Automatic LKD 970 Aluminum Foil Cover Lid Liner Die Cutting Machine is constructed from high-quality materials, including aluminum and steel components, to ensure durable and reliable performance. The machine features a micro-computer, human-computer control interface, servo positioning, and electromagnetic cluth centralized oil lubrication for smooth operations and precise positioning. With key parts and controls imported, the machine offers steady pressure, smooth movement, and safety and reliability, making it an ideal choice for aluminum foil production lines.

FAQ

WhatsApp: 0086-18930097829