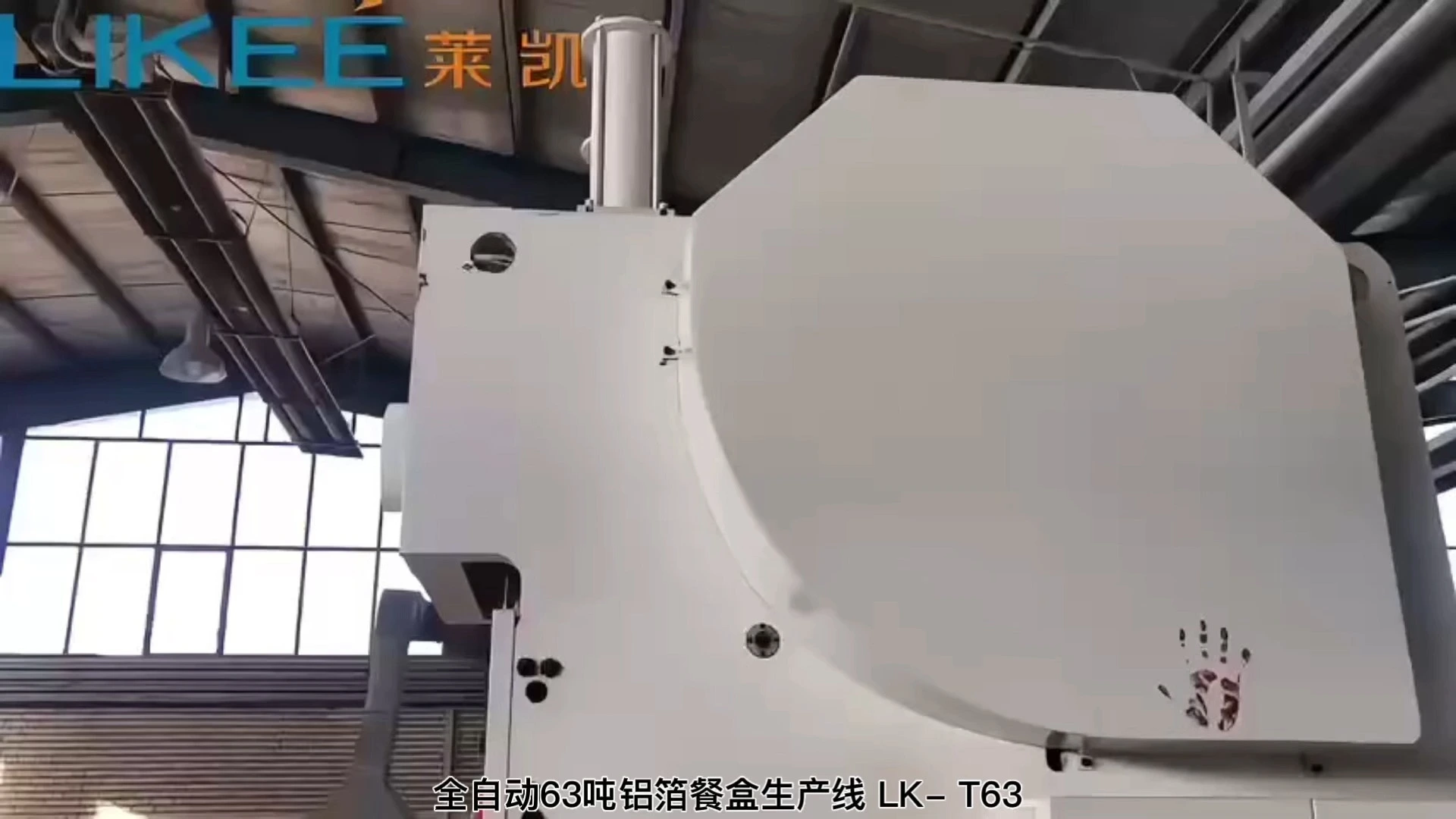

Energy Saving Aluminum Foil Container Making Machine with 63 Ton 3 Cavities

Energy Saving Aluminum Foil Container Making Machine with 63 Ton 3 Cavities

The full line LK-T63 includes components as below

- Decoiler 850mm

- Press Machine 63 Ton

- Auto Stacker With 3 Ways

- Scrap Aspirator

- Mould Lifter

- Scrap Baler

Advantages

1.Novel design for the roller of stacker,to assure the stronger stability.

2.Emergency stop with the automatic detection.

3.The width of the lanes can be adjustable to fit different size containers stacking.

4.CNC machining center, and its machining accuracy is very high.

5. Electric compelling grease lubrication system.

PRODUCT DESCRIPTION

Product Display

Efficient, High-Speed Aluminum Production

Efficient High-Speed Container Production

Energy Saving Aluminum Foil Container Making Machine with 63 Ton 3 Cavities is designed for 3 cavities mould production, suitable for small and medium size alufoil containers. Equipped with a safety door, automatic stop feature, and automatic counting, the machine ensures top safety and efficient operation with 60 sets mold parameter storage function and quick mold changing device. With a press capacity of 63 tons, installed power of 19.8kw, and electronic PLC Mitsubishi, the machine is efficient and reliable, backed by LIKEE's extensive experience in the aluminum foil container automatic production solution since 2010 and various certifications.

Application Scenario

Material Introduction

The Energy Saving Aluminum Foil Container Making Machine with 63 Ton 3 Cavities is made with a main body that features a sturdy "C" frame structure. The oil lubrication system utilizes lithium based esters for smooth functioning. Additionally, the machine is equipped with safety doors to ensure the highest level of operator safety. The press line T63 includes a decoiler, press T63, mould lifter, safety door, scrap aspirator, control cabinet, and a 3-way stacker, making it a comprehensive and efficient solution.

FAQ

WhatsApp: 0086-18930097829