Professional Insights: Choosing the Perfect Wrinkle Wall Aluminum Foil Container Mould

In today's retail landscape, packaging is more than just a means of protecting and presenting products. Its a critical aspect of brand identity, sustainability, and customer satisfaction. As a business owner, you need a packaging solution that not only enhances your product but also aligns with your sustainability goals. One such solution is the wrinkle wall aluminum foil container mould, which offers a unique blend of flexibility, durability, and eco-friendliness.

Introduction to Wrinkle Wall Aluminum Foil Container Moulds

Imagine youre trying to find the perfect packaging solution for a new product release. Your goal is to ensure your product is protected, branded effectively, and meets environmental standards. Thats where wrinkle wall moulds come in. These innovative moulds are designed to provide a sustainable, cost-effective, and flexible packaging solution that stands out in the market.

What Are Wrinkle Wall Moulds?

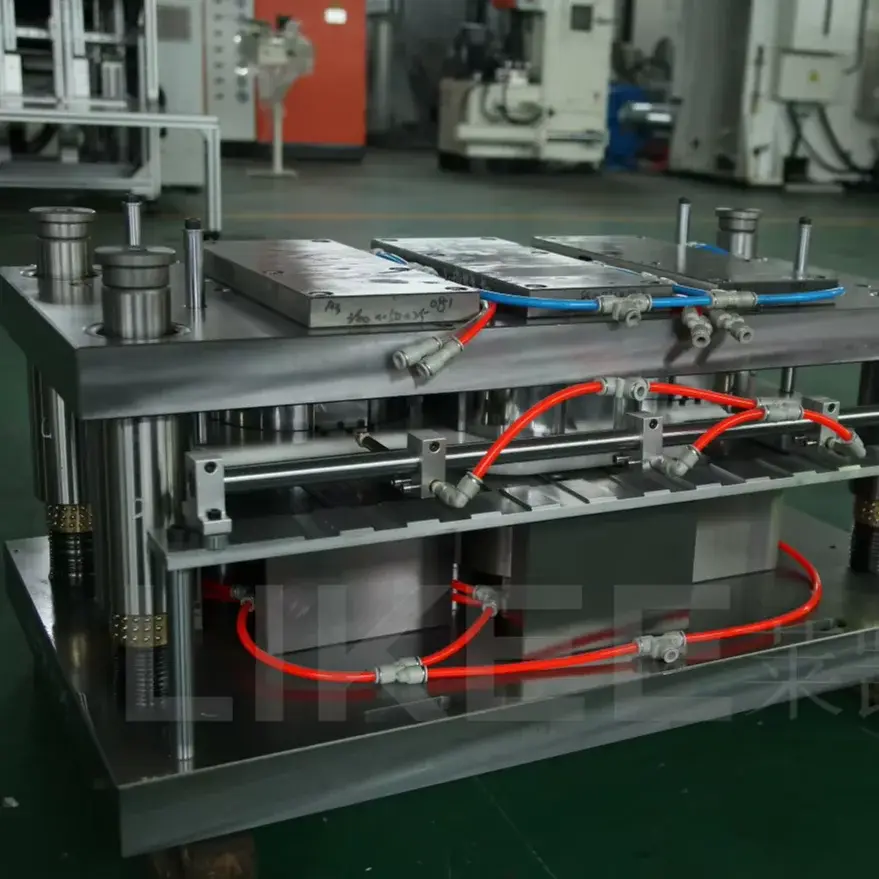

Wrinkle wall aluminium foil container moulds incorporate a series of folds and grooves into the surface, creating a visually appealing and functional design. This innovative approach not only makes the moulds more flexible but also enhances their durability and customizability, making them perfect for intricate packaging needs.

Key Features of Wrinkle Wall Aluminum Foil Container Moulds

Enhanced Flexibility

One of the primary benefits of wrinkle wall moulds is their enhanced flexibility. The folds and grooves allow for the creation of custom shapes and sizes, ideal for products with irregular dimensions. This flexibility ensures a tailored fit that maximizes protection and presentation.

Durability

Wrinkle wall moulds are typically made from high-grade aluminium, ensuring durability and resistance to wear and tear. The robust construction of these moulds makes them ideal for repeated use, reducing the need for frequent replacements. Imagine using the same mould multiple times without needing to replace it, saving both money and resources.

Customizable Options

The manufacturing process of wrinkle wall aluminium foil container moulds can be customized to meet specific needs. This includes the thickness of the aluminium foil and the design of the folds and grooves. Customization options are vast and can suit various products and packaging requirements, making these moulds a versatile choice.

Environmental and Cost-Effective Benefits

Wrinkle wall moulds offer both environmental and cost-effective benefits. They help reduce the use of plastic packaging, which is known for its non-biodegradable nature and contribution to environmental pollution. The aluminium foil used in these moulds is highly conductive and resistant to contamination, ensuring that products remain fresh and protected. Additionally, these moulds can significantly reduce production costs by minimizing material waste and extending the lifespan of packaging.

Advantages of Using Wrinkle Wall Aluminum Foil Container Moulds

Enhanced Product Protection

The use of aluminium foil in wrinkle wall container moulds provides excellent product protection. The conductive properties of aluminium ensure that products stay fresh and maintain their quality for longer periods, extending shelf life and reducing the need for additional preservatives.

Cost-Effectiveness

Wrinkle wall moulds offer substantial long-term savings. These moulds can significantly reduce production costs by minimizing material waste and extending the lifespan of packaging. Additionally, the customizability of these moulds means fewer molds are needed, further reducing overhead expenses.

Sustainable Packaging

Wrinkle wall moulds contribute to sustainable packaging practices. They help reduce waste and provide a more eco-friendly alternative to traditional plastic and paper-based packaging. The aluminium foil used in these moulds is highly conductive and resistant to contamination, making them an ideal choice for eco-conscious consumers.

Comparison with Other Packaging Solutions

Plastic-Based Packaging

Traditional plastic packaging is often criticized for being non-biodegradable and contributing to environmental pollution. While plastic is lightweight and easy to handle, it lacks the durability and resistance to contamination that aluminium foil offers.

Paper-Based Packaging

Paper-based packaging is highly sustainable and biodegradable but can be bulky and expensive. Wrinkle wall aluminium foil container moulds offer a balance between the two, providing a cost-effective and flexible alternative that is both durable and eco-friendly.

Why Choose Wrinkle Wall Moulds?

Wrinkle wall moulds stand out because they combine the best aspects of both traditional and modern packaging solutions. They offer a sustainable, flexible, and durable option that reduces waste and enhances product protection. With their unique design and functionality, these moulds are a practical solution for businesses looking to meet sustainability goals while maintaining high-quality packaging standards.

Practical Applications and Industry Use Cases

Dairy and Snack Industries

Wrinkle wall aluminium foil container moulds are ideal for packaging products like milk, cheese, and ready-to-eat snacks. The customizability and flexibility of these moulds allow for intricate designs that protect products and minimize waste. Imagine a cheese product packaged in a mould that not only keeps it fresh but also highlights its unique taste and quality.

Pharmaceutical Sector

In the pharmaceutical industry, wrinkle wall moulds are particularly valuable due to their ability to protect sensitive products. The high conductivity of aluminium ensures that the packaging remains safe and stable, meeting strict temperature and humidity requirements. Think about how a mould can help maintain the integrity of pharmaceutical products, ensuring they are safe and effective.

Household Goods

For businesses producing items like soaps, candles, and bath bombs, wrinkle wall aluminium foil container moulds provide a flexible and durable solution. The customizability allows for unique designs that enhance brand visibility and consumer appeal. Consider how a well-designed mould can make a product stand out on the shelves.

Case Studies

Businesses that have implemented wrinkle wall moulds have reported significant reductions in packaging waste and improved product protection. For example, a dairy company noted a 30% reduction in waste after switching to wrinkle wall moulds, while a pharmaceutical manufacturer improved shelf life by 25%. These real-world examples illustrate the tangible benefits of using wrinkle wall moulds in various industries.

Tips for Choosing the Right Wrinkle Wall Aluminum Foil Container Mould

Assess Your Product Requirements

Consider the shape, size, and weight of your product. Different moulds are better suited for specific products. Choose a mould that provides the necessary flexibility and protection. Think about the unique needs of your product and how a mould can meet those needs effectively.

Evaluate Material Flexibility

Ensure that the mould can accommodate the flexibility of your product. Solid moulds can handle various product types, ensuring product quality and protection. Consider how a mould can adapt to different product sizes and shapes, ensuring optimal protection.

Customization Options

Look for moulds that offer customization options such as colour coding, branding, and additional inserts. These features can enhance your packaging design and make it more appealing to customers. Think about how a mould can be customized to align with your brands aesthetic and marketing goals.

Manufacturer Collaboration

Work with reputable manufacturers who can provide high-quality moulds tailored to your needs. Partnering with experts ensures that the moulds meet your exact specifications. Consider the expertise and reliability of the manufacturer to ensure that your moulds meet your standards.

Trial and Error

Before committing to a full production run, test the mould with a small batch of products to ensure it performs as expected. This allows for adjustments and improvements before scaling up production. Think about the importance of testing to ensure the mould meets your quality standards.

Future Trends and Innovations in Wrinkle Wall Aluminum Foil Container Moulds

The packaging industry is constantly evolving, and wrinkle wall aluminium foil container moulds are no exception. Here are some emerging trends to watch:

Biodegradable Materials

Some manufacturers are developing wrinkle wall moulds made from biodegradable materials. These materials can be composted or recycled, significantly reducing their environmental impact. Imagine the future of packaging where materials are not only sustainable but also easily disposed of.

3D-Printing Technology

Advances in 3D printing technology are enabling the creation of even more intricate and customised wrinkle wall aluminium foil container moulds. This technology allows businesses to achieve a higher level of product protection and brand visibility. Consider how 3D printing can help moulds become even more tailored to specific needs.

Sustainable Packaging Practices

As more consumers become environmentally conscious, businesses are expected to adopt sustainable packaging practices. Wrinkle wall aluminium foil container moulds are well-positioned to meet this demand, making them a popular choice for eco-conscious consumers. Think about how your business can align with the growing trend towards sustainable packaging.

Conclusion

Wrinkle wall aluminium foil container moulds are a game-changer in the packaging industry, offering a perfect balance between cost-effectiveness, sustainability, and functionality. By understanding their features, benefits, and applications, businesses can make an informed decision that aligns with their sustainability goals and enhances product offerings. Imagine a future where packaging is not only effective but also sustainable and environmentally friendly and wrinkle wall moulds are at the forefront of this evolution.

-

-

-

2.2Durability

-

-

-

-

5.4Case Studies

-

-

WhatsApp: 0086-18930097829