Container Mould Safety: Key Considerations for Manufacturers

Navigating the Challenges of Container Mould Safety

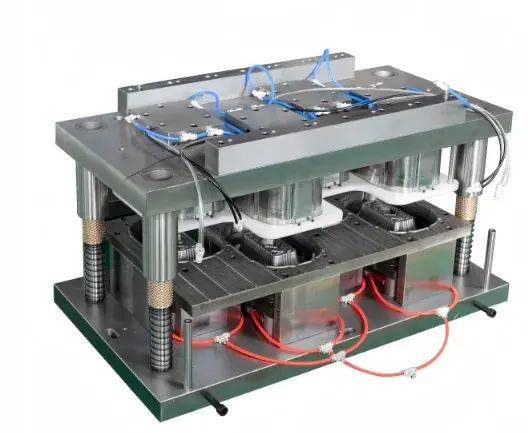

Container moulds are indispensable in the manufacturing industry, serving as the backbone for producing a wide array of packaging solutions. From food and beverages to industrial goods, these moulds ensure the integrity and safety of products during the manufacturing process. However, as industries increasingly rely on container moulds, the associated safety risks have not diminished. In fact, these risks have become more pronounced, necessitating a proactive approach to mitigate potential hazards.

The primary challenge manufacturers face is balancing efficiency with safety. While the production of container moulds is a vital part of industrial processes, neglecting safety can lead to catastrophic consequences. Chemical exposure, physical strain, and the risk of mold-related failures are just a few of the dangers that manufacturers must address. Ensuring that workers are protected and that operations are conducted safely is not just a legal obligation but a moral imperative.

Understanding the Risks: Hazards Associated with Container Mould Manufacturing

Container mould manufacturing is fraught with various hazards that can impact both workers and the environment. Physical hazards include exposure to harmful chemicals, particulates, and the strain from repetitive movements and prolonged standing. These factors can lead to long-term health issues and a high risk of workplace accidents.

Environmental risks are equally significant. Improper waste management and energy consumption can contribute to pollution and resource depletion. Additionally, the potential for mold-related fires or explosions cannot be overlooked, as these incidents can have devastating consequences.

The risks associated with mold failure and overheating are particularly concerning. A malfunctioning mold can lead to defective packaging, which not only compromises product quality but can also pose safety hazards. Ensuring that molds are maintained in optimal condition and that production processes are monitored closely is essential to prevent such occurrences.

Regulatory Compliance: Adhering to Industry Standards and Best Practices

Compliance with industry standards and best practices is a cornerstone of safe container mould manufacturing. Governments and regulatory bodies such as OSHA and ISO have set stringent guidelines to protect workers and the environment. Regular inspections and audits are required to ensure that manufacturers adhere to these standards.

Safety training and certification programs play a crucial role in safeguarding workers. Ensuring that employees are well-informed and properly trained can significantly reduce the likelihood of accidents. Additionally, maintaining up-to-date certifications is essential to comply with evolving regulations.

Case studies of manufacturers that excel in regulatory compliance provide valuable insights. These examples highlight the benefits of a proactive approach to safety and demonstrate how adherence to standards can enhance operational efficiency and worker well-being.

Design Considerations: Ergonomic Elements and Material Choices

The design of container moulds has a direct impact on worker safety and productivity. Ergonomic considerations are vital to prevent strain and injury. Designs that encourage natural movements and reduce awkward positions can significantly enhance safety.

Material selection is another critical aspect. Using durable and safe materials can mitigate the risk of contamination and wear and tear. Additionally, materials that are resistant to mold growth can help maintain the integrity of the manufacturing process.

Balancing ergonomic design with material choices ensures that workers are protected while maintaining productivity. These considerations are essential for creating a safe and efficient manufacturing environment.

Operational Safety: Ensuring Safe and Efficient Mould Operations

Operational safety encompasses a wide range of practices that ensure the safe conduct of container mould manufacturing operations. Regular maintenance and routine checks are essential to prevent equipment failure and ensure the safety of workers.

Safe handling and storage procedures are also crucial. Proper lifting techniques and secure storage solutions can prevent accidents and damage. Implementing safety protocols during the production process helps ensure that operations are conducted efficiently and safely.

The integration of technology, such as automation, can enhance safety in manufacturing operations. Automation not only improves efficiency but also reduces the risk of human error. By adopting advanced technologies, manufacturers can elevate their safety standards and ensure compliance with industry regulations.

Workplace Environment: Enhancing Safety Culture

Creating a safe and healthy work environment is a collective responsibility of all stakeholders in the manufacturing industry. Leadership plays a pivotal role in fostering a safety-focused culture. By setting the right tone and encouraging open communication, leaders can motivate employees to prioritize safety.

Effective communication strategies are essential in disseminating safety information. Ensuring that all workers are well-informed about safety protocols and emergency procedures can significantly reduce the risk of accidents. Additionally, creating a safe work environment involves addressing potential hazards and implementing measures to mitigate risks.

A strong safety culture not only benefits workers but also enhances overall business performance. When employees feel safe and supported, they are more likely to contribute to a positive work environment and achieve their full potential.

Future Trends: Innovations in Container Mould Safety

The future of container mould safety is poised to be transformed by emerging technologies. Innovations such as AI and IoT have the potential to enhance safety measures and improve operational efficiency. These technologies can provide real-time monitoring and predictive analytics, enabling manufacturers to anticipate and mitigate risks.

Emerging trends in safety innovation are driving the industry forward, offering new opportunities for manufacturers to elevate their safety standards. By staying ahead of the curve, manufacturers can ensure that their operations remain safe and efficient, even as the demands of the market evolve.

A futuristic outlook on the role of safety in container mould manufacturing highlights the potential for significant advancements. By embracing these innovations, manufacturers can set new benchmarks for safety and efficiency, driving the industry into a more sustainable and productive era.

Embracing Safety in Container Mould Manufacturing

In conclusion, ensuring the safety of container mould manufacturing processes is a critical priority for manufacturers. By understanding the risks, adhering to regulations, designing ergonomically, ensuring safe operations, fostering a safety culture, and embracing future innovations, manufacturers can mitigate risks, enhance productivity, and contribute to a safer and more sustainable industry.

Encouraging manufacturers to prioritize safety is not only a legal obligation but a moral responsibility. By taking proactive steps to safeguard workers, protect the environment, and improve operational efficiency, manufacturers can ensure the long-term success and sustainability of their operations.

Final thoughts remind us that a proactive approach to safety is essential in today's fast-paced and ever-changing manufacturing landscape. By staying informed, embracing best practices, and continuously seeking innovative solutions, manufacturers can navigate the challenges of container mould safety with confidence and achieve their full potential.

WhatsApp: 0086-18930097829